Air Sealing: Definition and Importance

Air sealing, or an air seal, is the process of creating an effective barrier within a building to prevent uncontrolled air exchange between the interior and exterior environments. When the climate-controlled air inside a building, adjusted to the optimum temperature for occupants and goods, escapes due to insufficient air tightness and poor ventilation management, it results in increased energy consumption and undesirable temperature fluctuations. Achieving a well-sealed building is essential for efficiency, reducing costs for building owners and contributing to carbon emission reduction and climate change mitigation.

Proper air sealing ensures minimized air leakage resulting in decreased energy requirements for climate control, leading to cost savings. By sealing gaps, cracks, and openings in the building envelope using techniques like weatherstripping and caulking, a stable indoor climate can be maintained, enhancing energy efficiency and reducing environmental impact.

Effective air sealing techniques and materials contribute to optimized energy efficiency, cost reduction, and environmental sustainability. By implementing air sealing measures, building owners can create a comfortable and financially beneficial environment while actively supporting a greener future.

Why is air sealing required?

- Building Regulations: Compliance with Approved Document Part L in England

- Energy Performance: Meeting the standards for fuel and power conservation

- Air tightness Testing: Ensuring adherence to regulatory requirements

What are the benefits?

- Heat Loss Reduction: Sealing imperfections with fire batt and mastic prevents air leaks and reduces heat loss

- Energy Efficiency: Improved thermal performance and lower energy consumption

- Indoor Air Quality: Prevention of drafts and pollutants entering the building

- Acoustic Seals: Additional benefits with the use of acoustic seals

- Overall Impact: Enhanced energy efficiency and healthier indoor environments.

How is air sealing achieved?

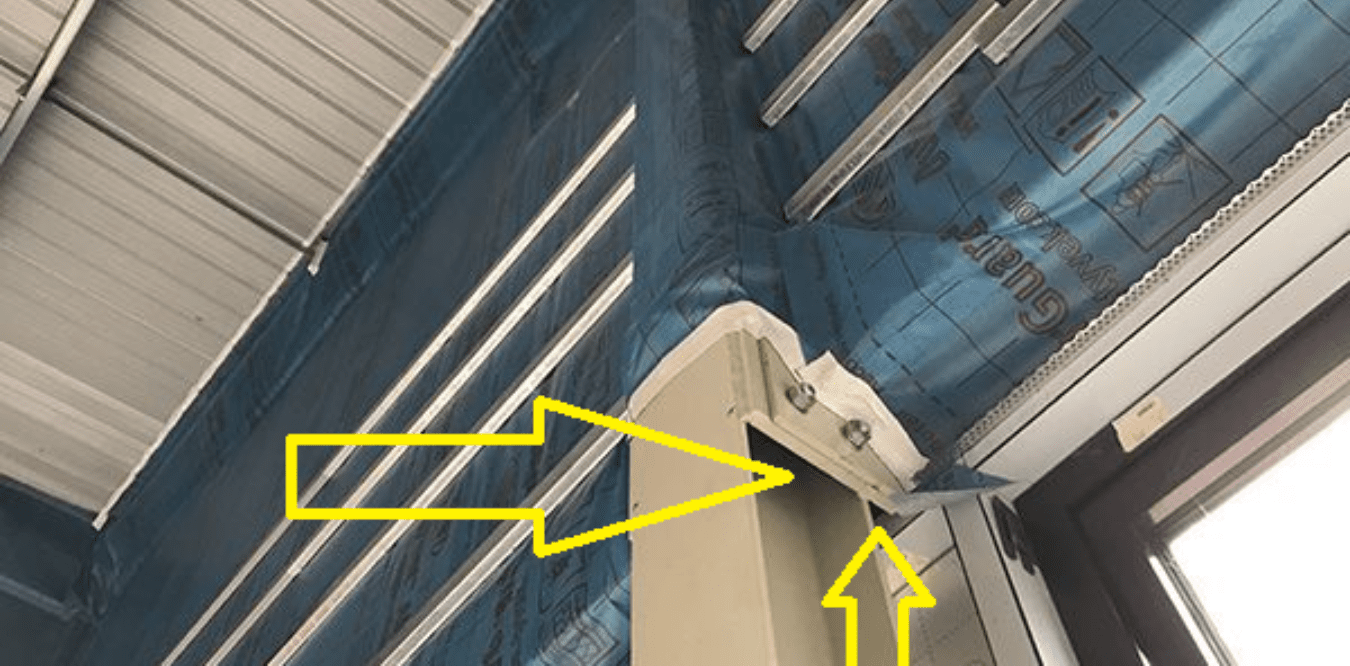

Installation of Vapour Barriers: Typically, vapour barriers, such as the examples provided by DuPont, are applied over the external envelope. While effective for sealing large areas, they can be challenging to use in smaller, intricate areas and junctions around fixings.

Fire Batt and Mastic: Fire batt and mastic offer flexibility, malleability, and fire and smoke-stopping properties. They are highly effective in restricting air loss and can be utilized to fill gaps and joints in external building junctions, particularly where internal walls and floors meet external facades and roof linings.

Expanding Foam: While expanding foam is a popular DIY option, it can be costly, messy, and wasteful. Moreover, most foam products are open-celled, prone to leakage if cut or damaged, and can degrade over time due to building expansion and contraction, leading to air leakage.

Versatility of Air Sealing: Similar to its application in preventing the transmission of smoke and sound, fire batt and mastic can effectively fill gaps and stop air leakage.