Fire safety is of the utmost importance in all buildings, regardless of whether they are residential or commercial. Passive Fire Protection (PFP) is a crucial aspect of fire safety that helps to contain, compartmentalize, and slow down the spread of fire. In this blog post, we’ll take a closer look at what PFP is, its importance, and how it is implemented in buildings.

What is Passive Fire Protection?

PFP refers to a range of methods and products that provide fire resistance in buildings. Its main purpose is to ensure that the spread of fire and smoke within a building’s structure and fabric is limited, thereby providing occupants with more time to evacuate the building.

In accordance with the Building Regulations (Approved Document B), all new builds, modernizations, and extensions must have PFP provisions in place. This includes both fire-resisting construction (sub-division of the building) and automatic fire suppression systems.

Passive Fire Protection is an essential aspect of fire safety in all buildings. Its main purpose is to contain, compartmentalize, and inhibit the spread of fire and smoke, thereby providing occupants with more time to evacuate the building. It is implemented through fire-resisting construction and fire-stopping measures to prevent the spread of fire through openings and joints. If you have any doubts about the best way to ensure PFP provision in your premises, please get in touch and we can offer a free non obligation review of your requirements.

How is Passive Fire Protection Implemented?

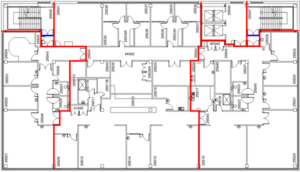

The Building Regulations state that measures must be taken to inhibit the spread of fire within a building to an appropriate extent, depending on its size and intended use. This includes the sealing of joints, imperfect fits, and openings for services, as well as fire-stopping to delay the spread of fire and smoke.

Fire-stopping is critical in preventing the spread of fire through openings for pipes and ventilation ducts. The regulations require that openings be kept to a minimum, are as small as practicable, and are fire-stopped to allow for thermal movement in the case of a pipe or duct.

Every time a new service is installed in a building, such as electrical sockets, water pipes, cable trunking, and lighting units, it will create an opening in the walls, floor, and ceiling. If these walls or floors are designated as fire compartment, they will need to be sealed with suitably fire-resistant products. The role of PFP is to seal these gaps, should a fire break out. All PFP products are fire-rated and certified to resist fire for a specified length of time, ranging from 30 minutes to 4 hours. Some products are inert and resist fire due to their robust composition and others contain an intumescent material that swells when exposed to heat, providing fire resistance.